You design it.

We machine it.

Park Precision Machining, Inc can help you from prototype development through final production. Following rigorous procedures developed by industry experts, we provide CNC parts fitted to your exact specifications.

Hours

Mon-Thurs 7:30am-4:30pm and Friday 7:30am-12pm

Service area

Minneapolis, MN Metro

Contact

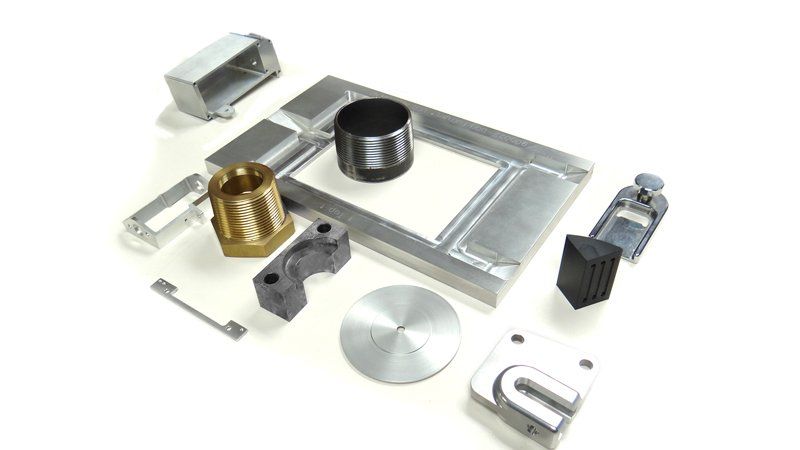

Our CNC Services

A myriad of other tools at our disposal plays well in the grand scheme of production

A variety of vertical, and multi-axis machining centers establish short and medium runs

A myriad of other tools at our disposal plays well in the grand scheme of production

Manufacturing Innovation.

Providing prototype and short to medium run production machining requirements for sophisticated applications is our specialty. Having electrical and air drops placed throughout the shop allow us to easily move machines to create efficient and effective modular work stations. Modular work stations and various other innovations allow us time to focus on quality and efficiency.

CNC Machining at Its Finest

Park Precision Machining is committed to meeting your CNC / Machine Shop needs. We offer close tolerance CNC Milling, Drilling, Tapping and Turning on state-of-the-art Precision Machining equipment. We commonly work with a wide range of materials suited to different industries and specialize in both short to medium run productions and prototypes.

Prototype 1 – 2 Parts

Short Run 2 – 25 Parts

Medium Run 26 – 250 Parts

100% Quality and On Time Delivery Ratings

29

Years of Experience

>500

Successful Projects

12

Cross-trained Professionals

"I had a pulley that needed a shaft shortened. Mike helped me out with it, and it turned out perfectly. Turned out that the factory fully had a .020 variation. He went to the center of the variation and cut the exact amount off to make it fit, went a step or 2 more than I expected for higher precision. Highly recommend."

Jason Bodin

“When we need parts quickly, without having to worry about quality, I know we can depend on Park Precision. We appreciate how closely they work with our engineers, helping keep parts as simple as possible, yet insuring that they will function as the design intended.”

Vic, Delta Industrial – Customer for 25 Years

“The folks at Park Precision are always extremely helpful and bend over backward to help us out when we find ourselves in a jam for product. After six years of working together on parts development and production, I can honestly say they’re like having the best employee around!”

Tracey Cramer – Leader Motorcycle Accessories

Welcome to

Design.

Quality.

Innovation.

We offer experience in processing many materials including carbon, alloy, stainless and tool steels as well as most non-ferrous materials including many grades of plastic. We have seen an increase in Aluminum castings for machining.

Serving Minneapolis and Beyond.

Minnesota CNC Machining

Park Precision Machining was founded in Spring Lake Park, MN in 1984. Our dedication to our customers’ needs has allowed us continuous growth. Since then we have grown steadily into our current facility in Minnesota.

National CNC Capabilities

We can ship CNC projects wherever you desire and can run production at competitive prices.

BUILDING TOGETHER

A Broad Range of Capabilities with Superior Customer Service

01

Engineering Perfection

We can take your great designs and manufacture them efficiently, with consistently high quality.

02

Bullseye Precision

One big thing that defines us is our capability to produce products with extreme accuracy.

03

Empowering Your Industry

We serve a broad range of industries throughout the US and beyond.

04

Cutting Edge Innovation

Our state of the art facility offers you the ability to submit projects to specifications not offered elsewhere.

FAQS

Got questions? We’ve got answers.

-

Why should I choose PPMI for my CNC machining project?

At PPMI, we have 29 years of experience in CNC machining. We have streamlined the process of protyping and production so that your CNC machining experience is as stress-free as possible. We work to your precise specifications to make sure your order is perfect every time. Our state of the art workspace allows us to seamlessly move your CNC machining project from station to station for quick production and delivery. We work with a variety of industries for both small and medium sized runs. Our CNC machining capabilities include: running, tapping, turning, CAD/CAM programming and much more. Contact us today to get a quote for your CNC machining project!

-

What are your business hours?

We are open Monday-Friday, 9-6

-

Do you offer national service and delivery?

Yes, we are located in Minneapolis, MN, but offer service nationwide. Contact us today to get a quote on your CNC machining project!

-

What are your guarantees for cosmetic standards?

All CNC machined parts must undergo normal deburring and edge breaking processes. Technical designs must make it obvious if there are any essential edges that should be left sharp. Surfaces will be devoid of minor flaws including hanging marks, scratches, dents, stains, and other flaws. The primary (a) side, as shown on the technical drawing, will be free of mill steps and other marks on the surfaces designated as critical. Small hanging marks and up to two minor flaws are permissible on the secondary (b) side. The surface roughness, aesthetic qualities, and wear resistance of machined parts can all be improved by the use of various post-processing and finishing techniques.

-

Is there a way to reduce costs on my project?

The primary expenses incurred by CNC machining can be divided into four categories: machining time, start-up expenses, material expenses, and feature expenses. You must comprehend how these elements affect prices if you want to lower them.

Designing features that can be machined fast, such as selecting the proper radii for internal corners, decreasing cavity depth, raising wall thicknesses, restricting thread length, and creating holes with uniform diameters, is the greatest strategy to shorten machining times.

By taking into account the size of the blank needed, as well as the price and machinability of the bulk material, material costs can be decreased (softer alloys are faster to machine).

Starting costs can be decreased by cutting down on the number of rotations or repositionings necessary to complete the part, for instance by breaking up geometries into separate sections that can be put together afterwards.

By deleting all text and lettering, employing tolerances only where absolutely essential, and avoiding various surface treatments, feature costs can be brought down.

Tell us about your machining challenge.