Our Services

Milling.

Park Precision Machining performs precision CNC milling services for our customers by utilizing a variety of CNC Machining Centers. Our dedicated production machines have pallet changers to maximize machine spindle utilization. We currently machine parts from Delrin, UHMW, Nylon, Wrought and Cast Aluminum, Brass, Steel, and Stainless Steels, to name a few materials. Our strategic machining selection allows for quick setups, which will reduce your new product development and assembly / check fixture costs while maintaining excellent quality.

Drilling.

Park Precision has CNC drilling services that are available for those items that need accurate holes. Our machines and cutting tools reliably provide cost-effective and accurate holes.

Typical operations include:

Drilling

Drilling and tapping

Drilling and thread milling

Drilling, end-mill bore (for location) and reaming

Tapping.

Park Precision Machining Inc. performs CNC tapping to produce components for a variety of industries. Our CNC machining and turning equipment is fast, has incredible accuracy, and is highly productive. All materials are inspected throughout our manufacturing processes. Quality is rigorously stressed and in-process inspection makes sure all parts meet or exceed customer requirements.

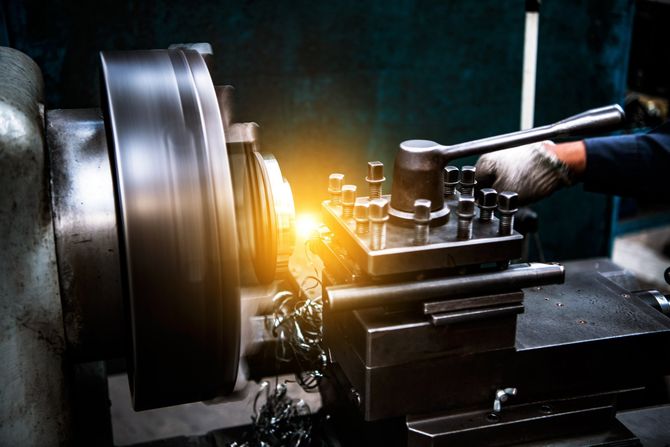

Turning.

Park Precision Machining’s fully certified machinists provide state-of-the-art turning in our coon rapids machine shop. We feature the latest CNC Mills and CNC Lathes to cut steels, composite materials, exotic metals, aluminum, and plastics to suite your needs.

We’ve found that CNC Turning provides a cost-effective way to make parts. We commonly combine our Turning with Milling processes to make more complex parts in a variety of sizes. To learn more about our services and how we can help you, please contact Park Precision Machining Inc. today.

Engineering & Design.

At Park Precision Machining, our expert staff has manufactured just about any kind of CNC machined part imaginable. Our customers are able to leverage our experience and expertise in the machining industry to assist with technical design and engineering. If you have questions about capabilities or challenges that need innovative solutions, we are happy to help.

Tool & Fixture Design

At Park Precision Machining, our goal is to make your idea a reality. We can take your idea, concept, or even napkin sketch and move forward with the design and manufacturing processes. This helps serve a dual purpose to check the basic viability and functionality of the part while also making sure that the end product is able to be manufactured in a realistic and cost effective manner.

Our experts use the latest version of SURFCAM, BOBCAD, and GIBBSCAM to reduce project lead-time and cost. Another service we provide is in designing and building custom fixtures and tooling to assist with the assembly and machining of products.

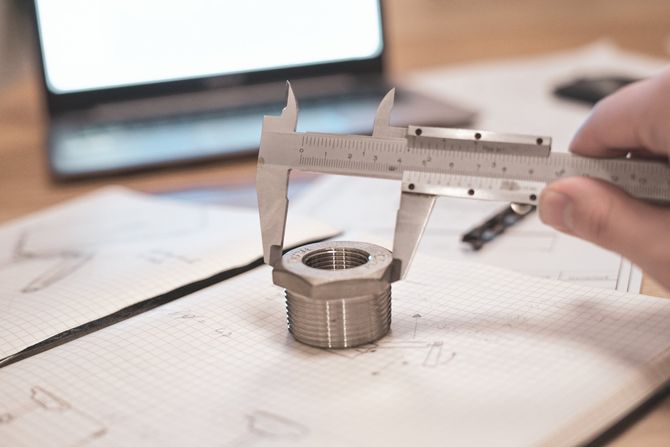

CAD/CAM Programming

Park Precision Machining can assist in your CAD/CAM needs and provide accurate design solutions. Our professional staff will work with you to turn your ideas into tangible producible products. This can be as small as single part to assemblies containing thousands of components.

Specialized Machining

Having a myriad of other tools at our disposal plays well in the grand scheme of production. This is a list of things we use to augment our CNC and CAD operations:

- Coordinate Measuring Machine (CMM) with PC-DMIS CAD software and a TesaStar-i probe head

- Marvel Automatic Cut Off Band Saw

- Surface Grinder (12 x 24)

- 30″ Vertical Band Saw

- Sunnen Horizontal Honing Machine

- Universal Tool and Cutter Grinder

- Profilometer

- Optical Comparitor

- Romer Absolute 7520 Portable Arm with Verisurf Software